Shingle Studies

JIVE Pre-Oxidation Shingle Coating

JIVE is better than the competition and doesn't result in a shingle coating with poor weathering performance. Adding JIVE to asphalt before oxidation (also known as blowing), can improve the penetration while not reducing the softening point substantially.

JIVE's use as an additive appears to alter the chemical composition of the asphalt such that the penetration and softening point relationship changes in a favorable way. JIVE reduces the viscosity of the shingle coating, which can significantly improve plant processing.

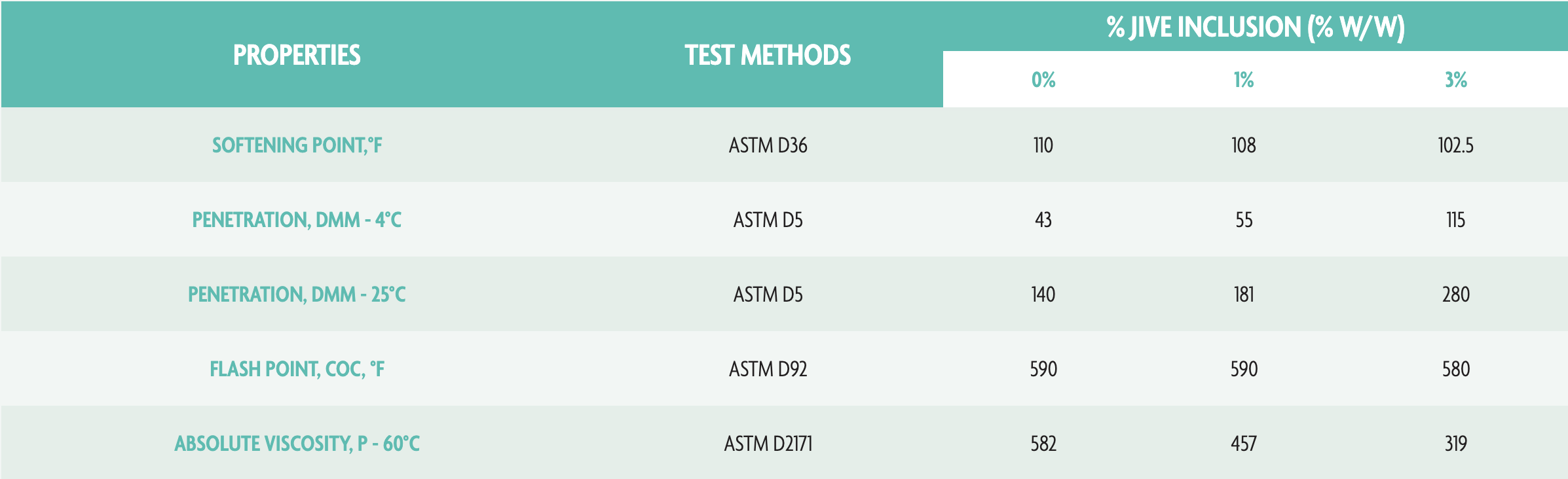

Table 1: Properties of Original Flux and JIVE/FLUX Blends Prior to Oxidation

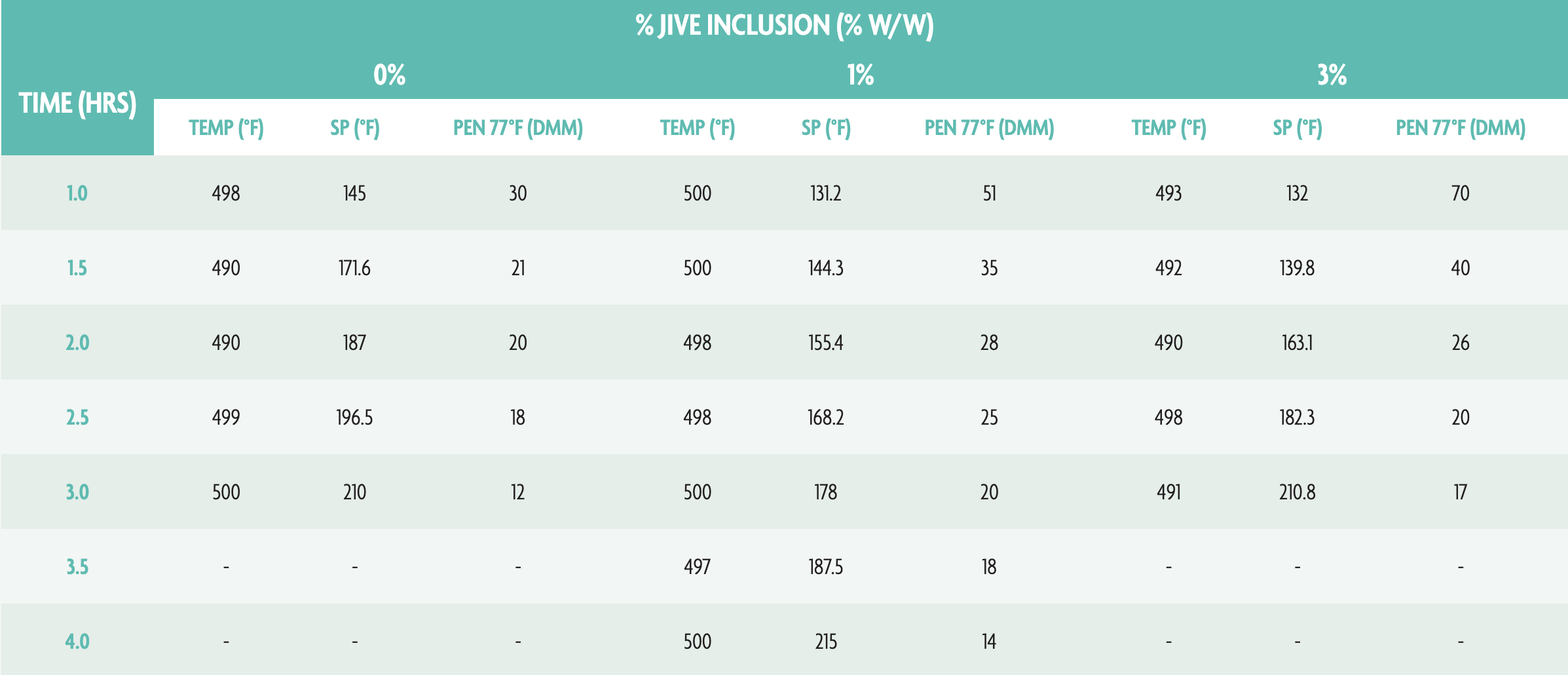

Table 2: Effect of JIVE Addition to Asphalt Exposed to Oxidation

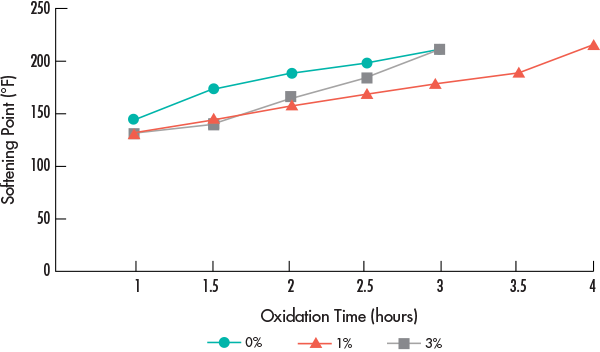

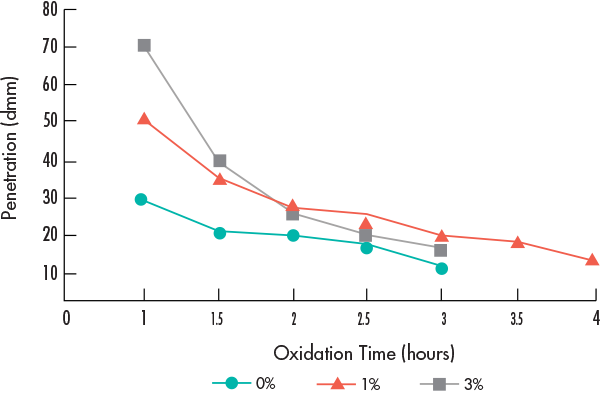

JIVE was added to asphalt at different percent inclusions (0%, 1%, and 3%) and then exposed to oxidation. See table 2, as well as figures 1 and 2. The softening point and penetration of the blends were evaluated over oxidation time. Oxidation was ceased once a target softening point of 210oF or higher was achieved. The softening point and penetration relationship appear to shift favorably at four hours of oxidation for 1% inclusion and three hours of oxidation for 3% inclusion. With JIVE inclusions in early oxidation time, the softening point results in greater than 3% reduction for every 1% JIVE inclusion and a 17% or greater increase in penetration for every 1% JIVE inclusion. However, at the optimal oxidation time for 1% JIVE inclusion, the softening point is increased by ~2%, and the penetration is increased by ~5%. 3% JIVE inclusion increases softening point by ~0.1% and increases the penetration by ~11%.

Figure 1: Effect of JIVE Addition on Softening Point to Asphalt Exposed to Oxidation

The starting softening point of JIVE inclusions start lower but is increased over oxidation time. After four hours of oxidation, the 1% inclusion reaches a softening point similar to that as the 0% at three hours. A similar result is observed with 3% inclusion at three hours.

Figure 2: Effect of JIVE Addition on Penetration to Asphalt Exposed to Oxidation

JIVE was added to asphalt at different concentrations (0%, 1%, and 3%) and exposed to oxidation. The starting penetration of the JIVE inclusions start higher but is decreased over oxidation time. After four hours of oxidation, the 1% inclusion maintains a higher penetration value to that of the 0% inclusion. A slightly higher penetration value is observed with the 3% inclusion at three hours compared to 1% after four hours.

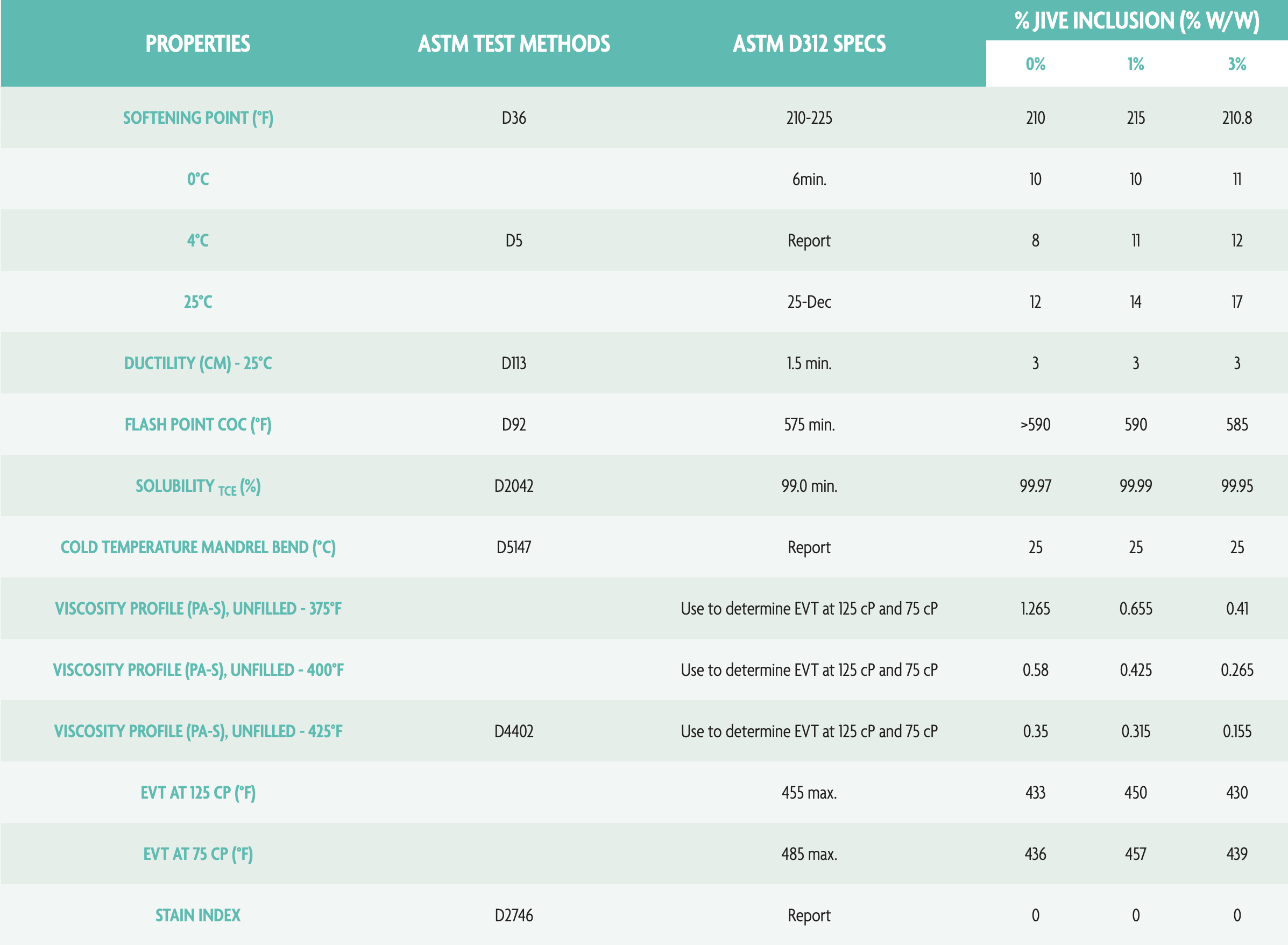

Table 3: Properties of Final Shingle Coatings After Optimal Oxidation Time

Properties of the shingle coatings produced at various JIVE concentrations (0%, 1%, and 3%) in asphalt exposed to oxidation are shown in table 3. Tested properties include softening point, ductility, flash point, solubility, cold temperature Mandrel Bend, viscosity profile, and stain index. Results indicate multiple benefits of JIVE inclusion, most notably a higher penetration value with similar softening point and lower EVT.

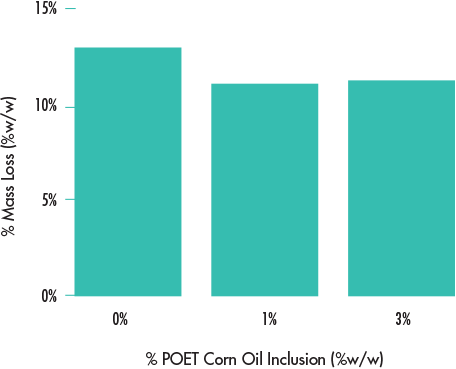

Figure 3: Weatherometer Mass Loss Results of Shingle Coatings

Panels generated from shingle coating produced at 0%, 1%, and 3% addition of JIVE before oxidation were exposed to accelerated weathering by Xenon Arc Weatherometer according to ASTM G155 for 3000 hours. Results indicated no pinholes or cracks in any of the samples, but an approximate 14.9% reduction in mass loss for 1% and 13.1% reduction for 3% JIVE containing shingle coatings. The average of two panels is shown for each sample type.