Rejuvenator Studies

Asphalt Binder Studies

In order to evaluate rejuvenation of aged asphalt by JIVE™, bending beam rheometer (BBR) and dynamic shear rheometer (DSR) tests were carried out on asphalt binder extracted from recycled asphalt pavement (RAP). The asphalt binder was a PG 58-28 from the upper Midwest/Northern tier states. BBR and DSR were carried out on the original asphalt binder, as well as the asphalt binder aged by rolling thin film oven (RTFO) and pressure aging vessel (PAV20, 20hrs 100°C, 2.1 MPa air pressure). Rejuvenation was assessed by the obtained BBR and DSR values after the addition of JIVE or other rejuvenators to PAV20 aged asphalt binder.

Bending Beam Rheometer (BBR) and ΔTc

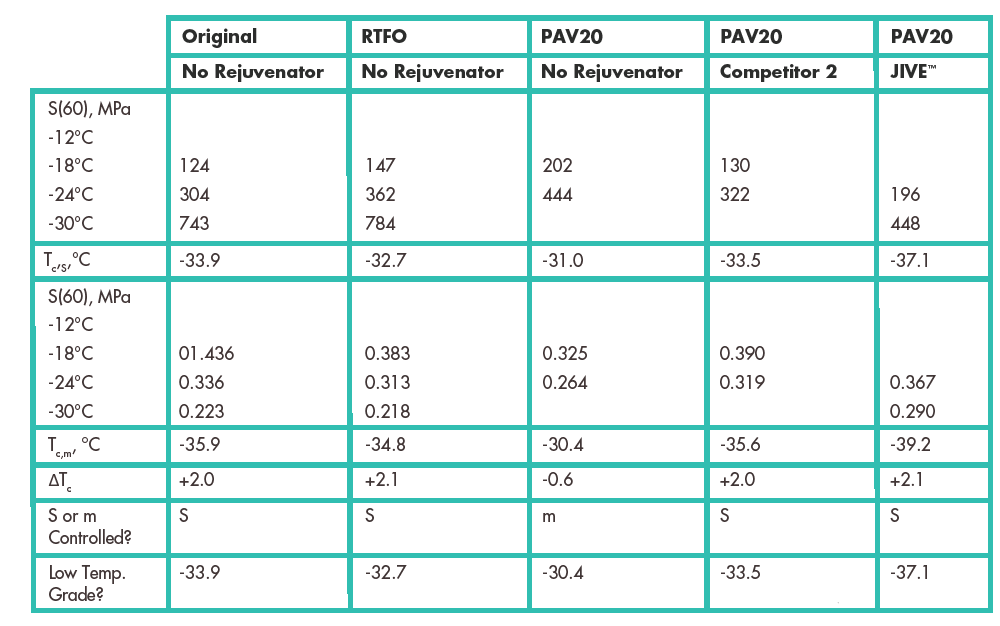

Table 1: BBR Test Results for Asphalt Binder Blends with and without Rejuvenators at 4% Inclusion

BBR tests show both rejuvenators reduced the stiffness (S(60) values) and increased the relaxation properties (m(60) values) of the aged asphalt binder. Since POET’s JIVE reduced the stiffness and increased relaxation properties better than Competitor 2, less JIVE can be used to obtain the desired effect.

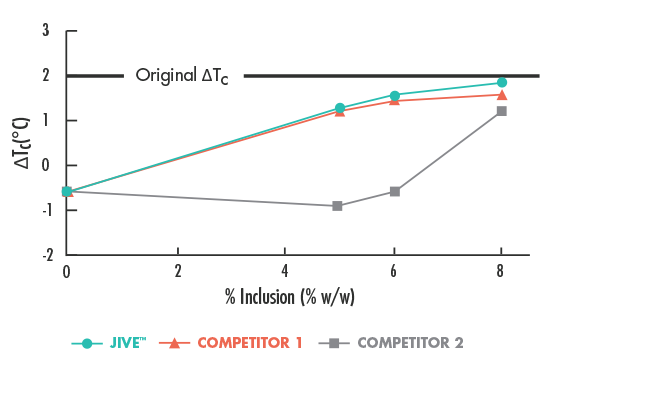

Figure 1: Effect of Different Percent Inclusions of Rejuvenators on ΔTc of Aged Asphalt Binder

The difference between the continuous stiffness temperature (ΔTc,s) and continuous relaxation temperature (Tc,m) measured by the bending beam rheometer (BBR) test is identified as ΔTc. As asphalt is aged the ΔTc parameter decreases, indicating a reduction in asphalt durability. As shown, aged asphalt binder was mixed with either JIVE or a competitor rejuvenator at 5%, 6%, and 8% inclusion. Results indicate a dose-responsive increase in ΔTc with JIVE indicating better relative durability than the blends with the competitor rejuvenators. The ΔTc of the aged asphalt (0% inclusion) had a value of -0.6°C. The ΔTc of the asphalt prior to aging is plotted on the graph with a value of +2.0°C.

Dynamic Shear Rheometer (DSR)

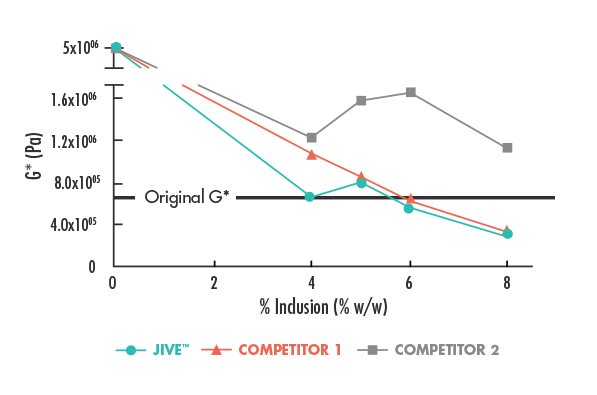

DSR test results were used to generate master curves at reference temperatures as a means of comparing the effect of different inclusions of rejuvenators on the complex shear modulus (G*) and phase angle (δ) of aged asphalt binder. For easier data interpretation, the percent inclusion of rejuvenators and their effect on complex shear modulus (G*) and phase angle (δ) at a single temperature (22°C) and loading frequency (10 rad/s) are shown below in Figures 2 and 3, respectively.

Figure 2: Effect of Percent Inclusion of Rejuvenators on Aged Asphalt Complex Shear Modulus (g*)

The effect on G* (stiffness) from different percent inclusions of the rejuvenators are plotted in Figure 2. The stiffness of the PAV20 aged asphalt is the value at 0% inclusion of rejuvenator. The stiffness of the original asphalt binder prior to aging is shown as the black horizontal line. All rejuvenators show reduction in stiffness of the aged asphalt. JIVE and Competitor 1 soften the aged asphalt more efficiently than Competitor 2 due to a viscosity driven effect.

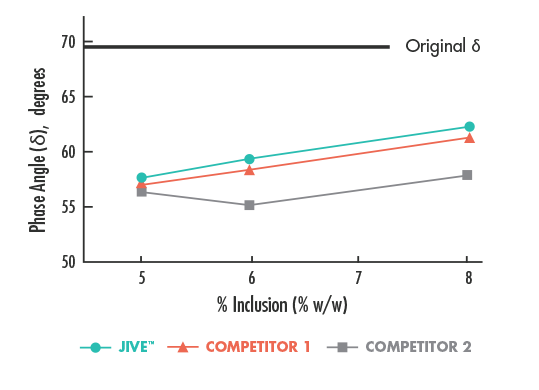

Figure 3: Effect of Different Percent Inclusions of Rejuvenators on Aged Asphalt Phase Angle (δ)

The effect of different percent inclusions of rejuvenators on the aged asphalt binder phase angle are plotted in Figure 3. The phase angle of the original asphalt binder is shown as a dark blue horizontal line. The phase angle of the aged asphalt binder is not shown. All rejuvenators increase the phase angle which is decreased during the aging process. However, addition of JIVE to the aged asphalt binder increases the phase angle more than the other rejuvenators indicating the blend is better able to recover the viscoelastic properties of unaged asphalt.

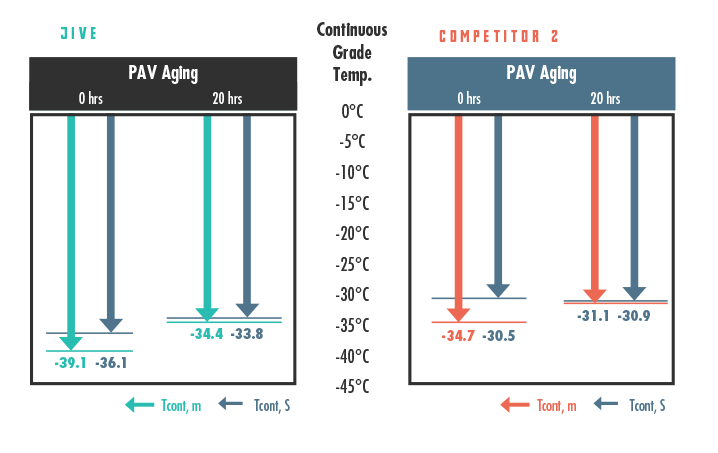

Figure 4: Effect of Extended Aging on Aged Asphalt Blends Containing Rejuvenators

Figure 4 illustrates the effect of aging on the low-temperature properties while rejuvenators are present during PAV20 aging. The continuous grade temperatures, stiffness (Tcont, S) and relaxation (Tcont, m) temperatures, before (0hrs) and after PAV aging (20 hrs), are plotted for both JIVE and Competitor 2. Competitor 2 is a petroleum oil-derived rejuvenator, whereas JIVE is a corn oil-based rejuvenator. This data demonstrates that much like petroleum rejuvenators, the inclusion of JIVE to asphalt does not negatively impact the aging process. In addition, JIVE offers better low-temperature improvement relative to Competitor 2.

Asphalt Mix Studies

In order to evaluate JIVE as a rejuvenator in asphalt mixes, various mix tests were carried out to evaluate its efficacy. Initial binder studies indicated that a typical 50% RAP mixture would benefit from the inclusion of 8% JIVE based upon the weight of the recycled asphalt binder in the asphalt mixture. Results from asphalt mixture tests including I-FIT, Overlay Tester, DCT, and Hamburg wheel-tracker, are shown below. Asphalt mixes tested include no RAP (virgin), high RAP content (50% RAP), and high RAP with 8% JIVE (50% RAP + JIVE).

Effect of JIVE on Asphalt Mix Containing High Recycled Asphalt Content

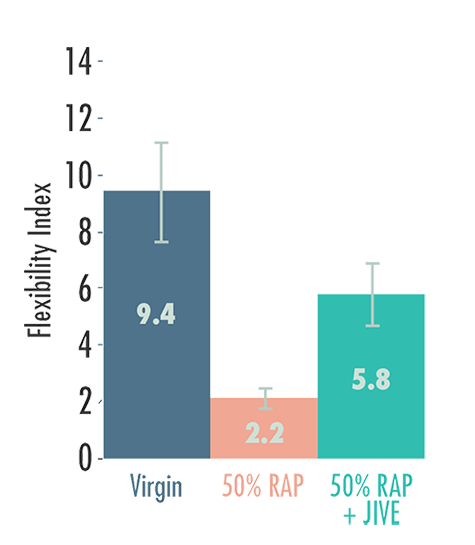

Figure 5: I-FIT Flexibility Index

The flexibility index of the mix samples as measured by the Illinois-Flexibility Index Test (I-FIT) following the Illinois Test Procedure 405 is shown in Figure 6. The data was produced at 25°C from four replicates of each sample. Inclusion of 8% JIVE by weight of the recycled asphalt binder significantly increases the flexibility index of a 50% recycled asphalt mix. The increase in flexibility index indicates enhancement in the recycled asphalt mixture’s resistance to fracture.

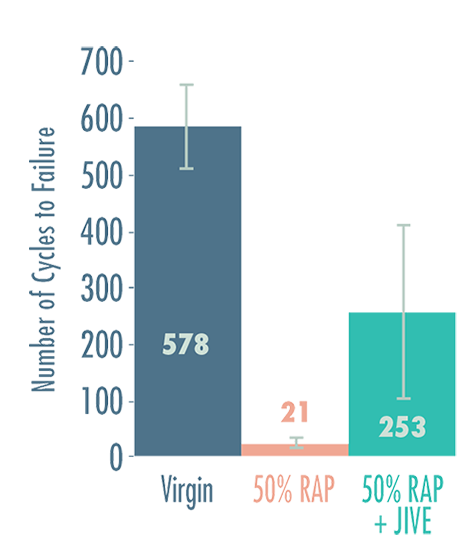

Figure 6: Overlay Tester Cycles to Failure

The number of cycles to failure as measured by Overlay Tester is shown in Figure 6. The test was run using a fixture and software within the IPC Global® Asphalt Mixture Performance Tester (AMPT). Data was collected at 25°C from four replicates from each sample while excluding outliers based upon ASTM E178 specifications. Inclusion of JIVE significantly increases the number of cycles to failure, indicating better fatigue and reflective cracking resistance at intermediate temperatures.

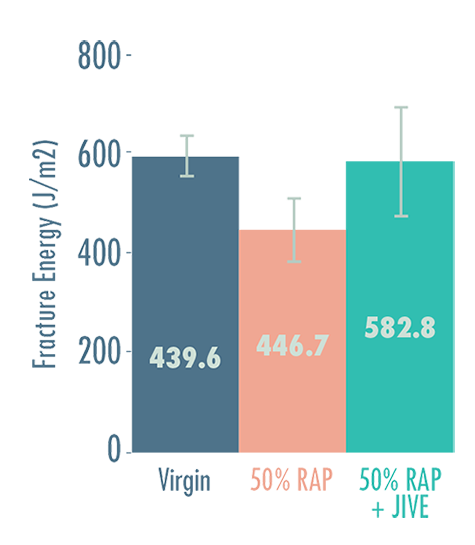

Figure 7: DCT Fracture Energy

Figure 7 plots the fracture energy measured by the Disc-Shaped Compact Tension Test (DCT) comparing various asphalt mixes. Data was collected according to ASTM D 7313-13 at -12°C from four replicates while removing outliers based upon ASTM E178 specifications. The results indicate that inclusion of JIVE in a 50% RAP mixture can improve low temperature cracking resistance.

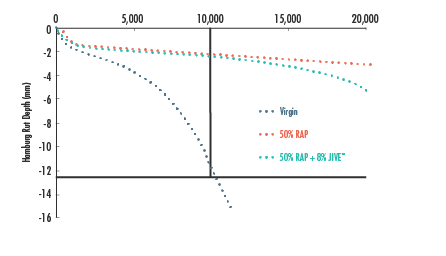

Hamburg Wheel Passes

Figure 8: Effect of JIVE on Hamburg Rutting with High Recycled Asphalt Mixes

Figure 8 shows the rutting susceptibility of asphalt mixes containing high levels of recycled asphalt with and without 8% JIVE compared to virgin mix. Data was collected by Hamburg wheel-track testing according to AASHTO T 324-14 from four replicates. The specification of 12.5 mm after 10,000 wheel passes is labeled on the graph. As shown, the inclusion of JIVE at 8% inclusion does not over-soften the 50% RAP mixture and therefore does not facilitate excess rutting in the rejuvenated mixture.

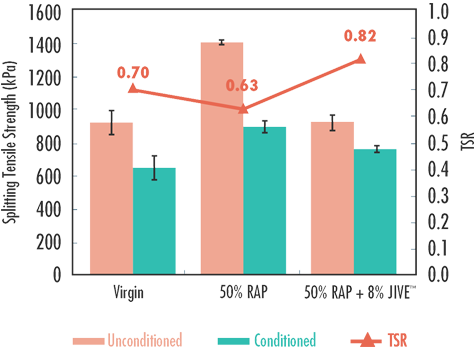

Effect of JIVE on TSR and IDT Results

In order to evaluate the moisture susceptibility of asphalt mixes without any added antistrip, indirect tensile strength (IDT) before and after conditioning was evaluated in accordance with AASHTO T283. Figure 10 shows the resulting tensile strength and tensile strength ratio (TSR) of both unconditioned and conditioned asphalt mix samples of virgin, 50% RAP, and 50% RAP with 8% JIVE. The results demonstrate that moisture resistance is significantly improved with the inclusion of 8% JIVE in comparison to both the virgin and 50% RAP mixtures. The effect on stripping is illustrated in the images of specimens in Figure 11. The results indicate that JIVE appears to have antistrip capacity by improving moisture resistance and reducing the asphalt mixes susceptibility to stripping.

Figure 9: Tensile Strength Ratio (TSR) and Indirect Tensile Strength (IDT)

Figure 10: Specimen Profile After IDT Testing

Unconditioned Virgin

Conditioned Virgin

UnconditionedD 50% RAP

Conditioned 50% RAP

Unconditioned 50% RAP + 8% JIVE

Conditioned 50% RAP + 8% JIVE