Modification Studies

Proven Results

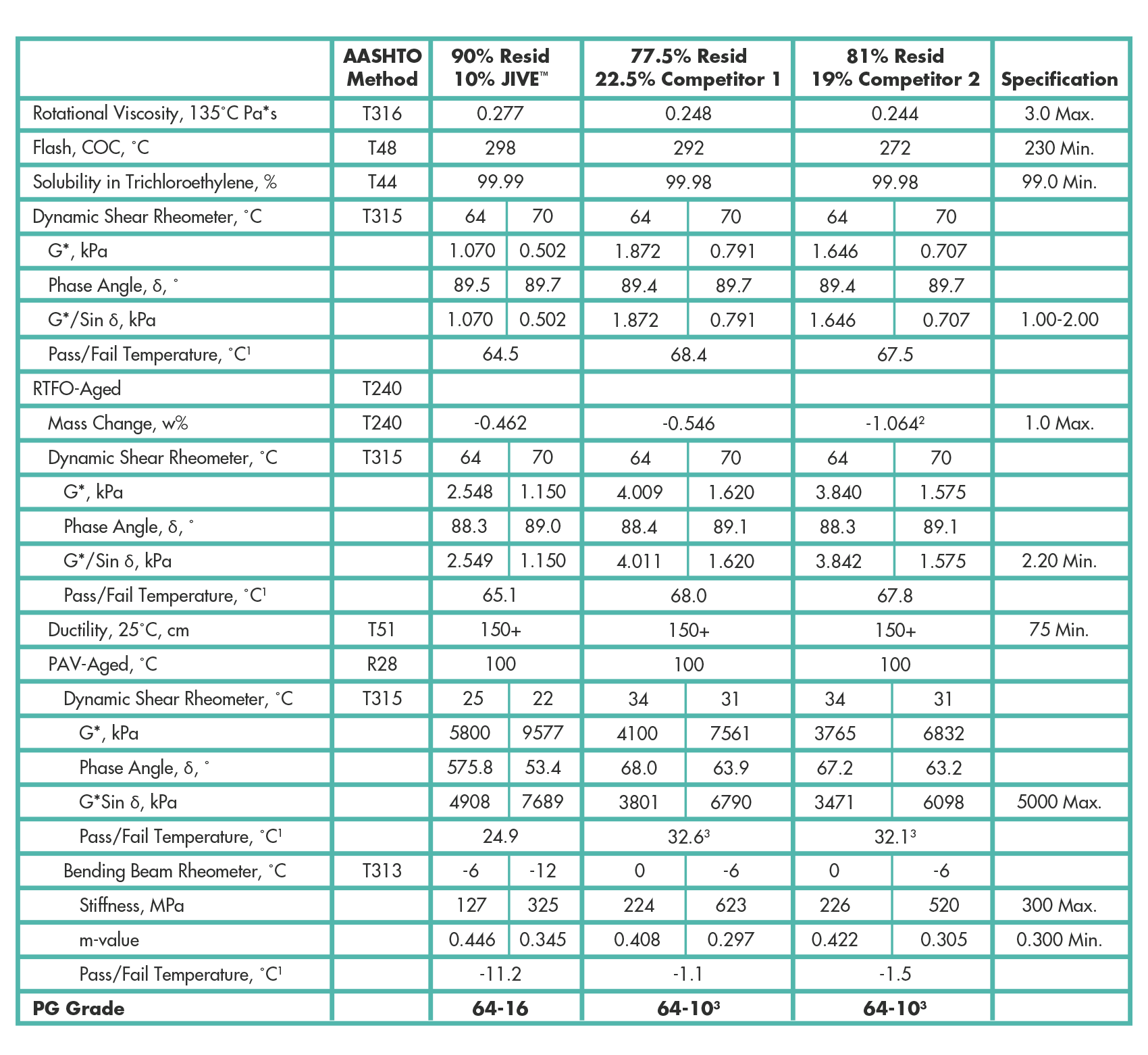

Various commercially available performance-grade (PG) modifiers, including JIVE™, were added to an oil refinery resid (G*: 29.90 kPa, Phase Angle: 86.6, G*/sinδ: 29.96, @ 64°C). An adequate inclusion of modifiers were added to satisfy the AASHTO T315 requirement for complex shear modulus elastic portion (G*/sin, 1.00 – 2.00 kPa). The results comparing the inclusion percentage and PG grades of JIVE against two competitor modifiers are shown in Table 1. Table 1 shows that 10% inclusion of JIVE into the oil refinery resid generates a 64-16, whereas 22.5% and 19.0% inclusion of Competitor 1 and Competitor 2 generate a 64-10 PG, respectively. Therefore, less JIVE is required to obtain a desired PG grade while offering better low temperature cracking resistance.

Table 1: Performance-Grade Evaluation with Jive and Two Competitors' Blends with an Oil Refinery Resid

1Pass/Fail temperature is the temperature at which the value of the material will be at the specification limit; 2Out of compliance value; 3To meet a PG 64-10 grade, the PAV DSR would have to pass at 31ºC

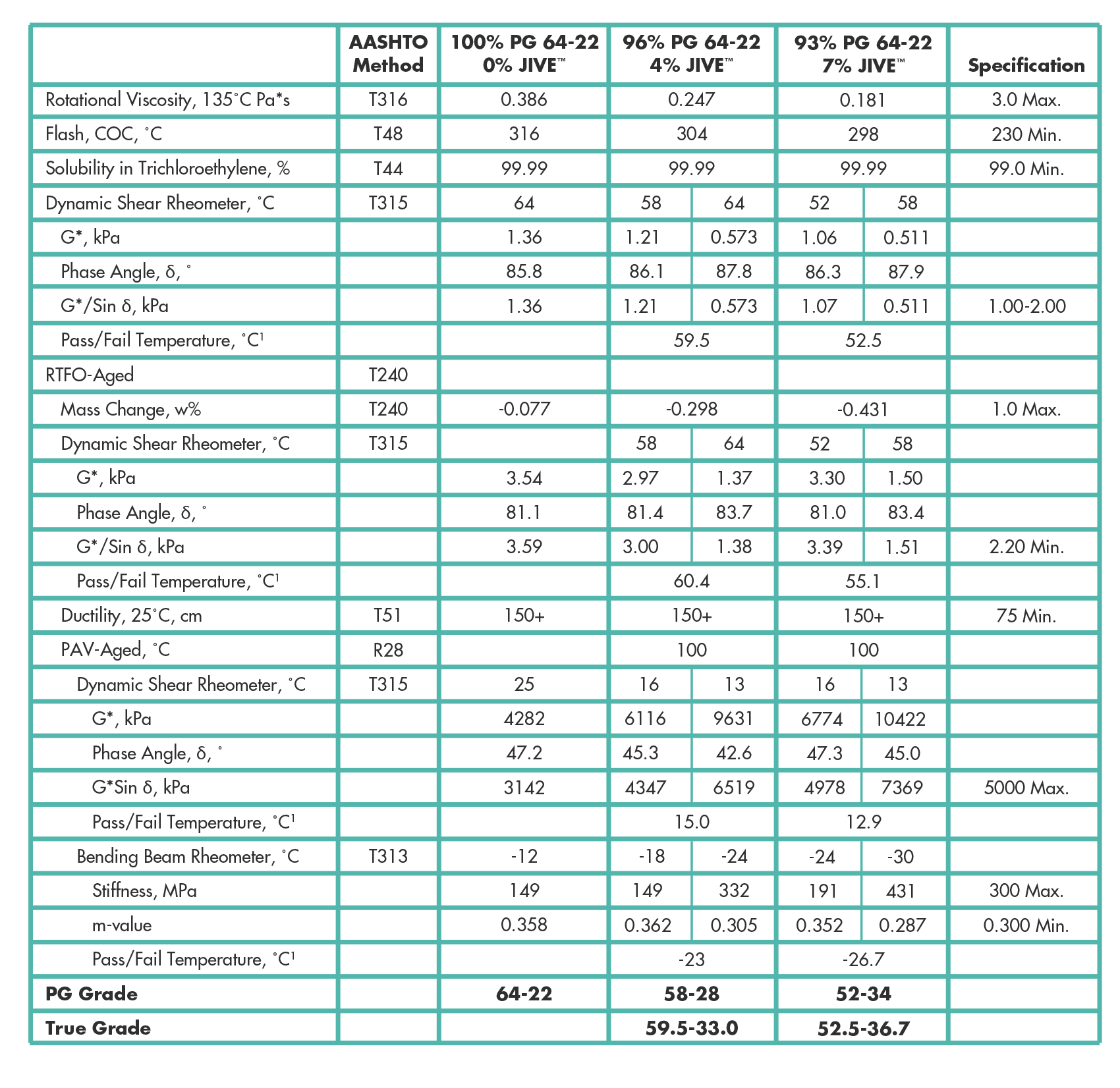

JIVE can also effectively modify PG asphalt to obtain different grades as desired. Table 2 demonstrates that addition of JIVE to a 64-22 asphalt binder obtained from a Midwest source is able to modify the PG to a 58-28 and a 52-34 with 4% and 7% inclusion, respectively.

Table 2: Performance-Grade Modification of 64-22 Base Asphalt Binder to 58-28 and 52-34 with JIVE

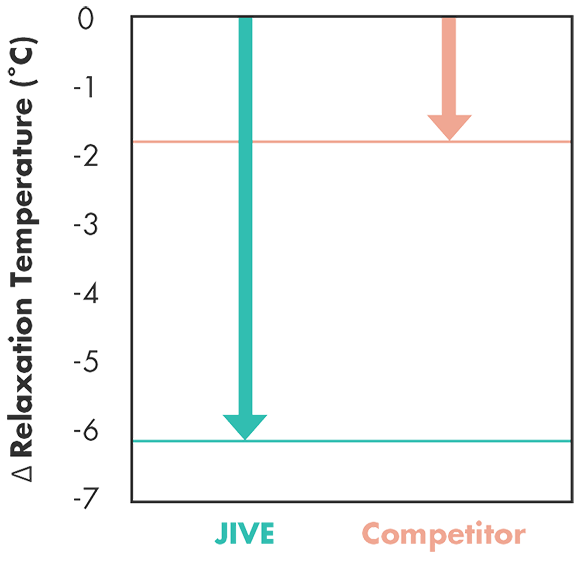

Figure 1: Asphalt Low-Temperature Enhancement with Jive Compared to Competitor

Figure 1 demonstrates that at the same inclusion rate, JIVE can improve the relaxation temperature dramatically in comparison to a commonly used competitor product. Data was collected by bending beam rheometer testing of asphalt binder mixed with 3% of either JIVE or Competitor. The change in the relaxation temperature is defined as the change in the continuous relaxation temperature (Tcont, m) before and after addition of each modifying agent.

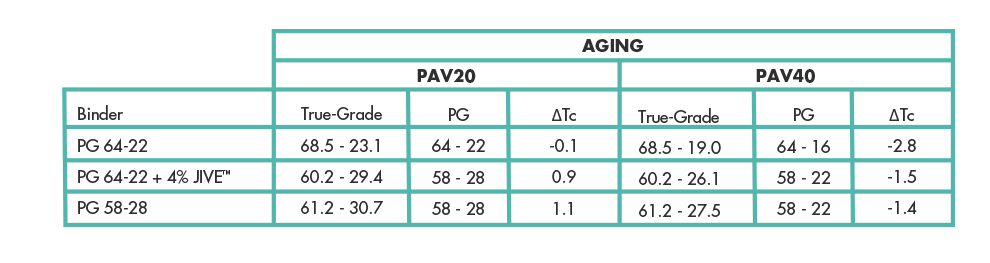

Table 3: Extended Aging Comparison of JIVE Asphalt Blends and Neat Asphalt

Asphalt Mix Testing

The JIVE blended 58-28 asphalt and neat 58-28 asphalt as previously described were used to produce mixes containing no antistrip additives in order to compare the mix performance of the two. Hamburg wheel tracking, Tensile-strength Ratio (TSR), and Illinois Flexibility Index Test (I-FIT) were used to evaluate mix performance.

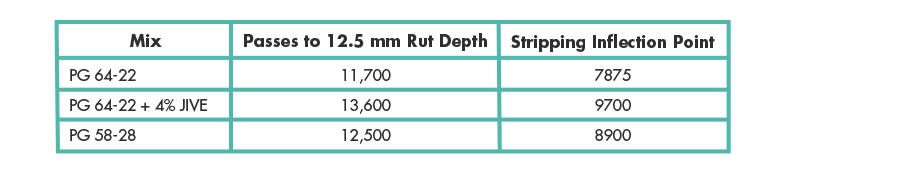

Table 4: Hamburg Evaluation of JIVE Asphalt Mix and Neat Asphalt Mix

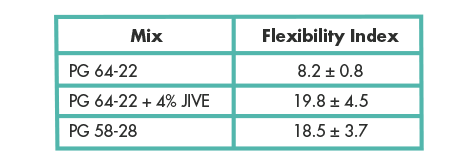

Table 5: I-FIT of JIVE Asphalt Mix and Neat Asphalt Mix

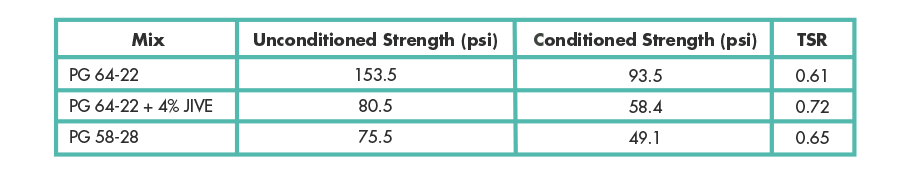

Table 6: TSR of JIVE Asphalt Mix and Neat Asphalt Mix

Hamburg rutting evaluation shows that the JIVE asphalt mix performed similar or better compared to the neat asphalt mix in terms of cycles to 12.5 mm rut depth and the stripping inflection point (Table 4). JIVE asphalt mix also performs similarly to neat asphalt mix in terms of I-FIT flexibility index (Table 5). In addition, JIVE contributes to improving TSR values as it performed better than the neat asphalt mix (Table 6). Overall, the data demonstrates that when JIVE is blended in asphalt, the produced asphalt mix performs the same or better than asphalt mixes containing neat asphalt of the same grade. This, along with other data collected on high RAP mixes, validates that JIVE, in addition to improving mix performance and reducing rutting susceptibility, has a slight antistrip benefit as well.