Press Releases

POET-DSM makes major technology, process purchase for commercial cellulosic bio-ethanol

Biomass treatment technology contracted with ANDRITZ, Inc.

Wednesday, October 24, 2012

SIOUX FALLS, SD (Oct. 24, 2012) – POET-DSM Advanced Biofuels has contracted for a key technology/process component in breaking down cellulose to produced advanced biofuel.

POET-DSM has contracted with International Technology Group ANDRITZ, through its U.S. subsidiary ANDRITZ Inc., to supply a two-step biomass treatment process for the commercial-scale cellulosic bio-ethanol plant under construction in Emmetsburg, Iowa. That technology will help draw out the available sugar in the collected biomass so it can be converted into clean-burning ethanol.

Project LIBERTY is expected to produce 20 million gallons per year of cellulosic bio-ethanol, growing to about 25 million gallons per year. The facility will use corn cobs, leaves, husk and some stalk to produce its renewable biofuel. Construction is scheduled to be complete in late 2013, and this fall farmers are increasing the amount of biomass delivered to the site in an effort to fine-tune storage efforts and get farmers used to the biomass collection process.

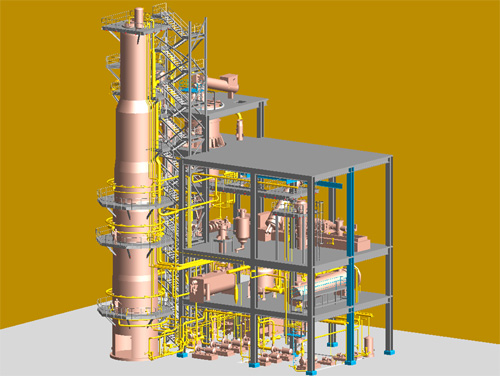

The ANDRITZ technology is a two-stage process that includes a vertical reactor, an interstage washer and then the continuous steam explosion technology (Advanced SteamEx™ process) to draw out available sugars from the cellulose material. It’s those sugars – through Project LIBERTY’s proprietary enzyme and yeast technologies – that get converted into ethanol.

“We’ve been working with ANDRITZ for over four years, collaborating on the development for a treatment process that aligns with our conversion technology development here at POET-DSM, and we selected them to provide that treatment process,” said James Moe, POET-DSM board member. “We’re happy to have them on-board. To say this has been quite a process is an understatement.”

Jay Miele, VP and General Manager with ANDRITZ Inc., is excited about the next phase in the project.

“Our design teams have been working closely together over the past four years to optimize our Advanced Steam-Ex pretreatment technology for Project LIBERTY,” Miele said. “POET-DSM’s dedication to becoming a leader in cellulosic bio-ethanol is quite evident to us. We look forward to successfully completing our part of the delivery for Project LIBERTY, and we are eager to work together on future projects.”

In March, company officials, as well as Iowa Gov. Terry Branstad, broke ground on Project LIBERTY, which is adjacent to POET Biorefining – Emmetsburg. POET and Royal DSM entered into a joint-venture agreement in January to form POET-DSM Advanced Biofuels. The two companies each hold a 50 percent share in the joint venture and are committed to bringing cellulosic bio-ethanol to the marketplace.

POET-DSM officials said the plant will hit its goal of collecting about 85,000 tons of corn cobs and light stover, which will prepare the plant for commercial success – all while adding a new revenue stream for Emmetsburg-area farmers. The harvest target represents an increase of 24,000 tons over last year’s harvest, as POET-DSM moves toward collection of 285,000 tons of biomass per year for Project LIBERTY at full scale.

As the fall harvest continues, the plant has taken in most of the contracted 85,000 tons of biomass so far. Through a managed collection model, POET-DSM arranged for the custom harvest and transportation of biomass for area farmers.

About POET-DSM Advanced Biofuels, LLC

POET-DSM Advanced Biofuels, LLC, is a 50/50 joint venture between Royal DSM and POET, LLC. Based in Sioux Falls, South Dakota, the company is a cooperative effort of two innovators that provides a key to unlocking the opportunity of converting corn crop residue into cellulosic bio-ethanol. Built on the strengths of both companies, the joint venture has a critical mission: to make cellulosic bio-ethanol competitive with corn bio-ethanol, the most competitive renewable liquid transportation fuel on the US market today. Drawing on the deep expertise and experience of POET and DSM in different areas of converting cellulosic biomass into bio-ethanol, POET - DSM Advanced Biofuels will have its first commercial-scale plant co-located with POET' Biorefining -- Emmetsburg in Emmetsburg, Iowa. Based on this plant, the JV plans to globally license an integrated technology package for the conversion of corn crop residue to cellulosic bio-ethanol. More information: www.poetdsm.com